SPECIALIZED

SAFE

EQUIPMENT

MOBILITY

MOVE TRACKED EQUIPMENT SAFE AND FAST

When it comes to moving heavy machinery, ETT Lowbed Trailers are the most versatile equipment mobility solution available. With a loading time as low as four minutes, transporting equipment is safe and fast plus it decreases wear-and-tear on tracked equipment due to excessive tramming.

Engineered from the ground up, ETT Lowbed Trailers make use of high-quality components and superior design simulation techniques to ensure seamless performance in the toughest conditions.

WHAT CAN YOU DO IN UNDER 4 MINUTES

Move tracked equipment safe and fast and drive tramming costs down. ETT's 130T Lowbed Trailer gets the job done.

ett@work

Meet the Team

-

COMPACT LOWBED TRAILERS

The carrying capacity of our compact model ranges from 40 Tonnes up to 420 Tonnes. Designed to load from the rear, the lowbed deck lowers to form a ramp with a 4.5-degree incline. The lowbed is raised and lowered with wireless remote control, thus the operator can conduct loading procedure from a safe distance and remain out of harm’s way.

The short and compact design makes this lowbed trailer a versatile addition to your fleet, featuring a tight turning circle and suited to a wide selection of haul trucks. A faster and safer rear loading design means that loading time as low as three minutes.

-

LONG WHEELBASE LOWBED TRAILERS

The rear-loading long wheelbase trailer ranges from 40 Tonnes to 420 Tonnes. Not only does the rear-loading feature offer the benefit of quick and efficient loading, but it also supports the safety aspect of not having to uncouple the trailer, as is the case with front loading trailers. Uncoupling often also necessitates a person to guide the driver to couple again and could also lead to hydraulic oil leaking from uncoupled hoses.

The low ramp angle ensures safe and easy loading of drill rigs and the continuous ramp angle has no break-over, which prevents the equipment from “rocking” while loading. The faster and safer rear loading design means that your tracked equipment can be loaded in as little as three minutes.

ARTICULATED WATER TRUCKS

-

SAFETY

The fully integrated wet brake management system is engineered to ISO 3450 and ensures safe travel on inclines and slopes, providing the correct levels of brake effort and cooling for safe and reliable operation. The brakes are oil-cooled for increased retardation performance and safety.

-

INNOVATION

ETT Lowbed Trailers feature a single axle design for pinpoint turning on most roads without the need for reversing. The cost-effective single axle design allows for cost savings through reduced tire scuffing when turning and reduced road damage during the U-turn process.

-

SUSTAINABILITY

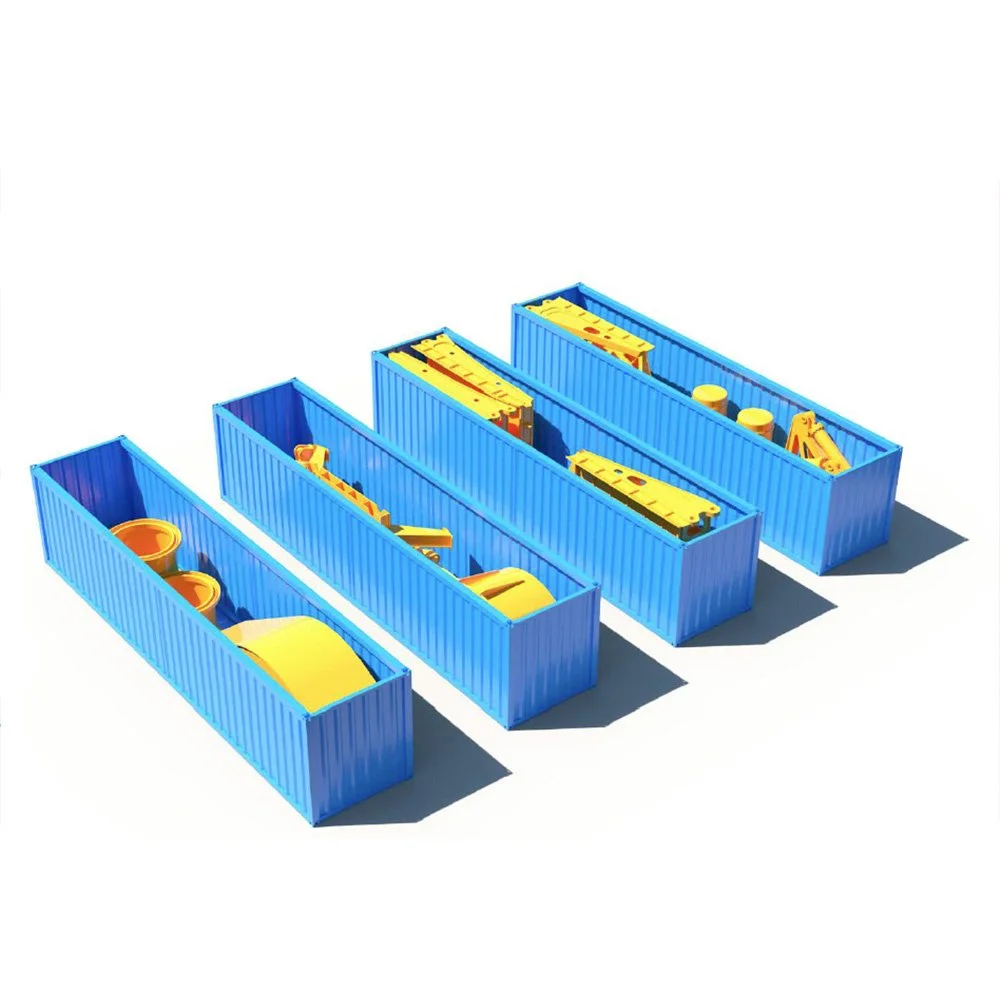

ETT’s innovative modular design of the lowbed is designed with ease of freight and assembly in mind. These lowbeds break up into manageable sub-assemblies that fit into shipping containers for economical and easy transport to site utilizing regular haul trucks instead of oversized transport.

Once on site, the components are pinned together with minimal effort and require no on-site welding. The modular design also allows for easy component replacement or upgrades. Single components such as the gooseneck for example can be swapped out at a later stage should the haul truck be changed.

-

ANTI-JACKKNIFE SYSTEM

ETT’s Anti-Jackknife System is an integrated automatic safety system designed to prevent a jackknife event from occurring during operation. The system works by measuring the loads exerted on the truck by the lowbed, and then applying a proportional amount of braking to the lowbed axle. Should the system detect that the lowbed is pushing the truck with a force greater than the allowable threshold, the system automatically starts to apply the lowbed brakes to reduce the pushing force from the lowbed.

-

SAFE LOAD SYSTEM (SLS)

ETT’s Safe Load System (SLS) is an intelligent safety system that guides the payload unit's operator to the perfect position on the load bed. It integrates seamlessly with ETT’s lowbed trailers. The system is designed to ensure that there is enough load transfer from the trailer to the haul truck and prevent unsafe operating conditions.

The Safe Load System utilizes strain gauges installed on the lowbed structure to measure internal stresses in the lowbed. The intelligent CAN bus control system monitors various parameters from the sensors and is calibrated to allow a minimum safe load transfer to the truck. If the load transfer is below the calibrated minimum, the lowbed trailer will not lift, and the park brake will not disengage.

-

HEAVY-DUTY BALL HITCH

Lowbed trailers connect to the haul truck via ETT’s durable, zero-maintenance heavy-duty ball hitch, which connects to the truck body through heavy duty pins, eliminating any welding modifications to the haul truck.

-

CUSTOMIZABLE DECK SURFACES

ETT Lowbed Trailers feature a steel deck as standard, which is fitted with heavy-duty cleats that provide additional traction for tracked machines to crawl onto the deck.

The ETT Gravel Deck is perfectly suited for tracked equipment as it provides maximum traction during loading and prevents any slipping during transportation.

ATTACHMENTS

-

QUICK AND SAFE RECOVERY SOLUTION

Need to recover large rigid mining trucks quickly and safely? Our Recovery Gooseneck is designed to recover and tow them safely away from the mine work area. The Recovery Gooseneck can be installed on a 250-ton rigid truck.

The system can be operated by two people – one driver for the towing truck, and one spotter who can safely direct the engagement procedure from the safety of the work deck on the rear of the tow truck.

WATCH OUR LOWBEDS OPERATE

SPECIALIZED SAFE EQUIPMENT MOBILITY

ETT's Mining Lowbed Trailers are packed with these features and benefits:

ISO 3450 certified to ensure safer braking;

OEM wet disc brakes providing engineered brake energy management;

5° continuous ramp angle prevents rocking over the ramp transition point;

Rear loading design for faster and safer loading (loading time under 4 minutes);

U-turn with ease on the haul roads or in the pit;

Single axle design for minimal tire scuffing.

Move drill rigs, large face shovels, bulldozers and excavators

Engineered from the ground up, our Lowbed Trailers cater for drill rigs and large face shovels, bulldozers and excavators, with single-axle design for pinpoint turning and ISO 3450 braking to stop on a dime. Move tracked equipment safe and fast and save on tramming.